What does powder coating actually mean

Durable, versatile, low-emission, efficient. Powder coating may not sound so glamorous, but if you want a colorful finish, there is hardly a better process for surface protection. Thanks to electrostatic effects, perfect surfaces can be produced. And when the going gets tough, they show character.

Text: Stephan Becker

Old men on the beach, painting their boats with a cigarette in the corner of their mouth: There's no question that classic wet painting can even have a certain romanticism attached to it. The word "powder coating" sounds more sober, like optimized production processes on an industrial scale. And indeed, the technology is not really for the home, even if there are now compact systems for the hobby cellar. Otherwise, powder coating actually only has advantages.

The basic principle is quickly explained. Paint particles are electrically charged by means of mechanical friction or an electrode and then atomized into a fine spray jet using an air pressure gun. According to the rules of electrostatics, these particles then adhere evenly to a necessarily conductive workpiece. With a special pre-treatment, materials such as plastics or wood-based materials can now also be coated. Finally, the workpiece is placed in the oven at around 180 degrees, where the particles fuse together to form a closed surface - a physical head instead of manual brushing.

In terms of their composition, powder coatings are not so different from conventional paints. Both use synthetic resins such as epoxy or polyester as binders. However - and this is a decisive advantage, particularly from an ecological point of view - solvents are not required for powder coating. Another advantage of the process is the quality of the surface. This is because the particles are evenly deposited on edges, openings and even rear surfaces. This results in a particularly robust and corrosion-resistant finish. All standard colors and surfaces are available, from high-gloss to matt, from smooth to textured. Effect coatings are also possible.

The development and spread of powder coating began relatively late. Due in part to stricter emissions regulations and new techniques for recovering excess paint particles, the process has become increasingly economical since the 1960s. And unlike catalytic processes, such as those used in the form of huge paint baths in the automotive industry, powder coating is also suitable for smaller series with varying finishes - ideal for steel furniture construction in particular.

Picture 1: Paint particles are atomized into a spray mist using an air pressure gun

Picture 2: At around 180 °C, the paint particles fuse together in the oven to form a closed, robust surface

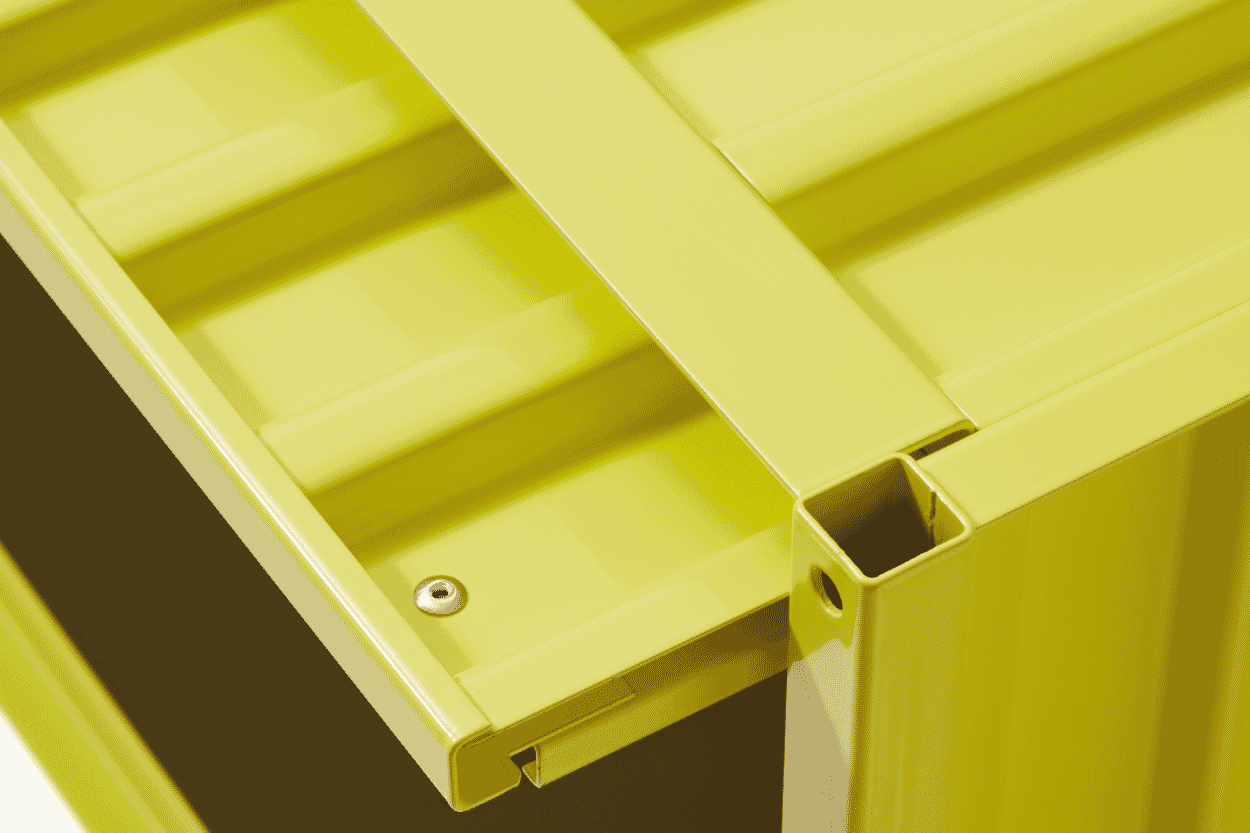

Picture 3: Detail of the CONTAINER DS made of powder-coated sheet steel in sulphur yellow

Pictures: eyeseedesigns, Adobe Stock; Ross Helen, iStock

POWDER-COATED AND ICONIC: THE CONTAINER DS

What does that actually mean...?

Corrosion protection usually means applying an additional coating. With aluminum, however, a little oxygen is enough. In the electrolysis process, the metal forms a hard and durable surface of aluminum oxide on its own. And it can even be colored

Raw, unadorned, radical - galvanized surfaces have a special aesthetic and often develop a fascinating beauty in combination with the material, shape and surroundings. At MAGAZIN, we value the material and use it in various products.