One - Set

With the EINSER, MAGAZIN has the first own chair in its range. The simple wooden model is manufactured in a young company in Slovenia, where the tradition of wooden furniture production goes back a long way. Exciting details add character - such as the colored metal brackets with which the backrest is attached.

Text: Bettina Homann

Can you say of a chair that it nestles comfortably against your body? It may not sound like an obvious description, but that's exactly what it feels like to sit on the EINSER. Thanks to a slight hollow, the seat does not press against the ischial tuberosities. The curved backrest provides support for the back without restricting mobility. A comfortable position is easy to find - no restless sliding around necessary.

The simple wooden chair is one of the latest additions to the MAGAZIN product range. But aren't there already an infinite number of chair models on the market? Is it really possible to invent something new? "Of course, it's a field where there's already a lot out there," says Daniel Kern. "But you definitely want to have a chair in your own collection. It's a charismatic piece of furniture and has a higher recognition value than a shelf, for example," says the designer and head of MAGAZIN product development. As signature pieces of a furniture collection and basic furnishings for every home, chairs are - from a human history perspective - a rather recent achievement.

Our ancestors sat on stones or hides. The first four-legged seats with backrests were reserved for emperors and kings. Until the 19th century, chairs remained an expression of wealth and power and were made by hand. It was not until the Viennese coffee house chair in the mid-19th century that industrial mass production began and prices became affordable.

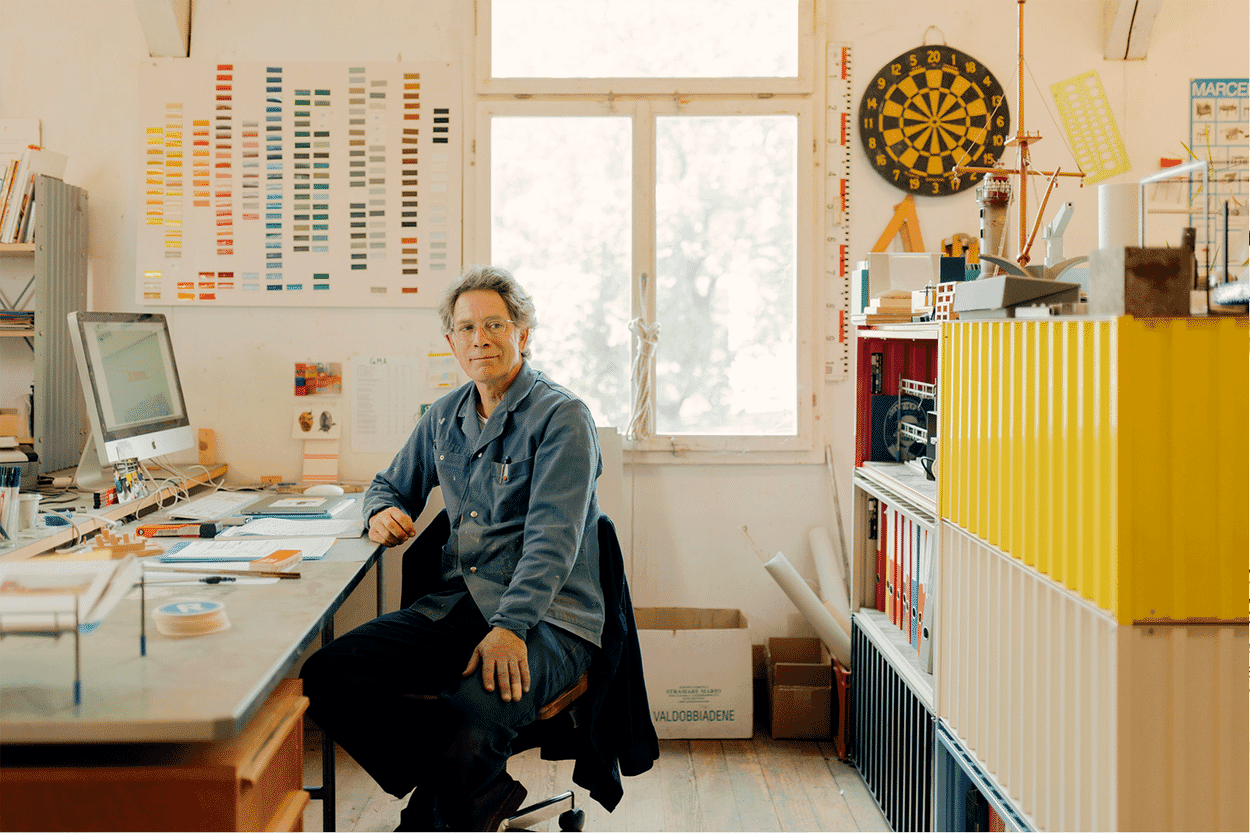

Daniel Kern welcomes you to the design office of MAGAZIN in Berlin, surrounded by prototypes from the in-house collection. There is the CMB chest, which not only provides storage but also functions as seating, the ZEHDENICKER table frame and many colorful DS containers. Stacks of drawings indicate that a lot of tinkering is going on here. A cloth bag with the inscription "Better done than perfct" hangs on a hook. However, the slogan is a little misleading - after all, the MAGAZIN design team is all about perfection. "The most important things for us are production in Europe, sustainability and cost-effective manufacturing through well thought-out design," says Kern. This led to the question: "How much can a chair be simplified without becoming arbitrary?" First of all, Kern paid a visit to L.ask in Borovnica. While researching production facilities for the chair project, MAGAZIN came across the company near the Slovenian capital of Ljubljana. The company has the necessary expertise - and is not so big that it would not be interested in the rather small initial run of the EINSER chair.

"Slovenia," explains Kern, "used to be big in wooden furniture manufacturing, with huge exports, but many companies went bankrupt." L.ask was able to take on trained specialist staff and machines from the traditional companies. For example, an automatic drilling machine developed for the production of so-called spindle chairs. "There was a green monster in the workshop with lots of drills in it, some of which were set at very strange angles." This gave rise to the idea of the semi-circular holes on the seat of the EINSER, into which round wood is screwed as chair legs. "This is both a beautiful detail and an extremely stable fit," explains Kern. Straight pieces of wood conserve resources, unlike curved ones, as they are not cut out of a larger piece.

The rounded cut-out below the backrest ensures balanced proportions. When Kern lifts the chair to point out this detail, gently running his hand over the smooth wood, he appears proud in his own understated way. Like a violin maker holding a special instrument in his hands. The backrest is connected to the rear legs by two color-contrasting metal brackets, giving the backrest lightness and springy comfort - and ONE a characteristic detail. "This connection makes the chair more comfortable, and we can set an accent here with our strong colors," says Kern. Apart from the glued connection between the frame and the seat, all parts of the chair are connected with screws that are clearly visible. This simple construction makes it possible to buy the chair not only fully assembled, but also flat-packed for self-assembly in the untreated version. The designer is particularly pleased about this. Flatpack saves a lot of volume and therefore CO2 during transport, and the untreated wood can be easily recycled.

MAGAZIN is therefore completely satisfied - which is reflected in the name of the new addition: "We are happy that we were able to master this ambitious project, meet our criteria - and also achieve a marketable sales price," explains Daniel Kern. "That's why the name EINSER stands for our first chair and is also a bit of a tongue-in-cheek school grade that we have given ourselves for it."

DANIEL KERN

Daniel Kern values the exchange with the partner companies of MAGAZIN. "We are always on the lookout for designs that will last for years in the collection. They are often created in consultation with the people who will later be responsible for production," says the head of MAGAZIN product development. The EINSER chair would also not have been possible without the commitment of the wood specialists from L.ask in Slovenia.

Chair EINSER

Discover more MAGAZIN products

Space-consuming and conventional - that's how we know the closet. But there is another way, as the new MAGAZIN product P100 shows.

When Kuno Nüssli's Container DS found its way into the MAGAZIN range, nobody would have dreamed that the product would one day become a bestseller. We visited the universal creative Kuno Nüssli in Basel.

The young designer Julia Dichte has developed a contemporary table linen series for MAGAZIN. EQUIPE is produced by a French weaving mill.