Which plastic we want to afford

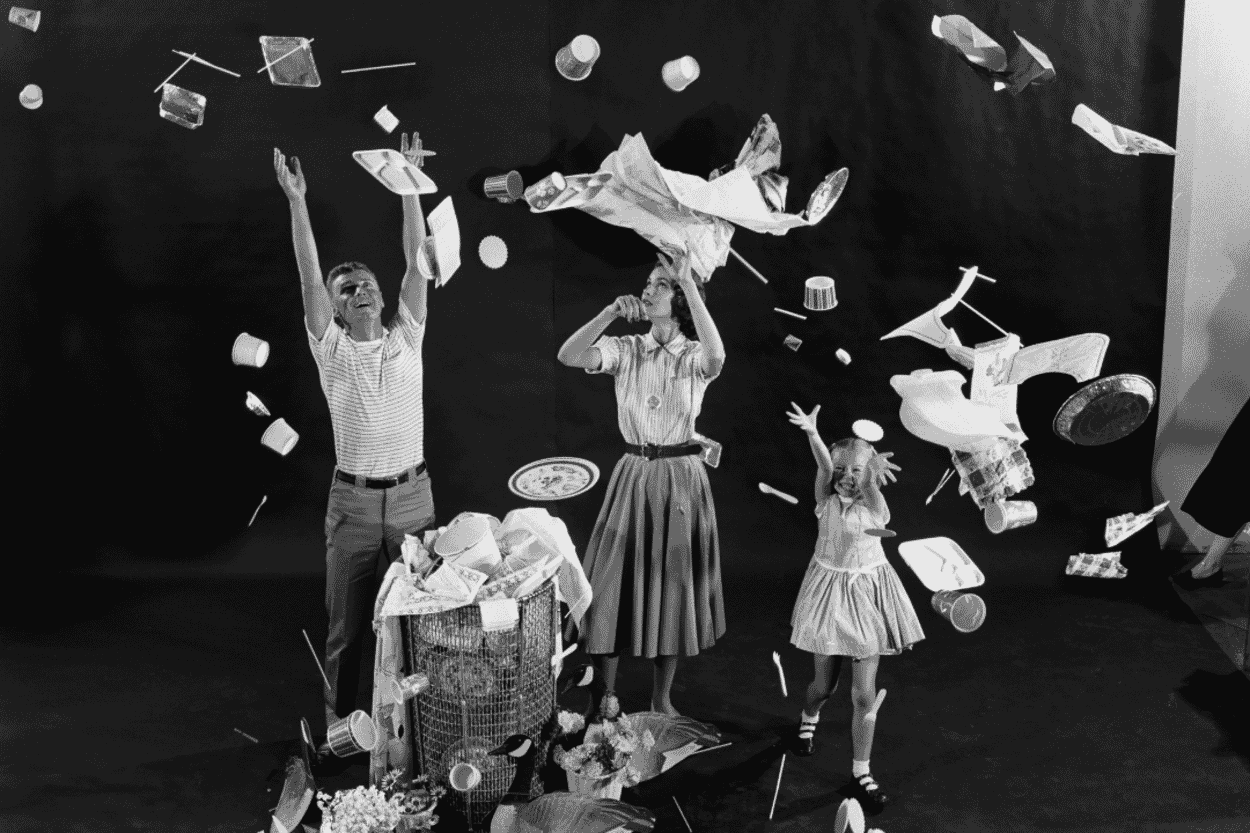

Time for a mind experiment! What if plastics were a valuable resource - and not seemingly endlessly and cheaply available? This change of perspective could help us break free from our toxic relationship with plastic. The goal: to consume plastics more consciously - away from single-use, towards long-term use, away from packaging that is quickly disposed of, towards sensible, recyclable plastic products.

Text: Jasmin Jouhar

Relationship status: It's complicated! On the one hand, we know only too well that we are polluting the environment and ultimately ourselves with our plastic consumption. But on the other hand, we can't let go of plastic. We have a literally toxic relationship with all the PET, PVC, polystyrene and polyester around us, a relationship that can be characterized by ignorance, self-deception or condemnation. Let's start with the ignorance: it has probably not escaped anyone's attention that there are huge whirlpools of waste in the oceans and that microparticles from decomposed bags, tire abrasion or textile fibers are found even in the remotest places in the world - and in the human organism. If you want to know more, you can easily find out that the production of plastic produces toxic substances, as does its incineration. And that the recycling of household waste has so far only worked to a limited extent and that our affluent waste is shipped to other countries.

But despite all these alarming findings: The production volumes of plastics and their consumption only seem to be going in one direction: upwards! We often ignore the damage we are causing - the climate crisis sends its regards. Psychologically, such behaviors have been explained many times; people think in the short term and suppress dangers that lie in the future. We are also simply very comfortable, and all those bottles, bags, foil and to-go cups come in handy. They are light, hygienic and can simply be disposed of after use. Never to be seen again - which is of course not true, see above. In fact, we can only afford our consumption-oriented lifestyle because plastics are cheap and available in large quantities. Packaging, household goods, clothing, toys, electrical appliances, vehicles - plastics are everywhere. Even the construction industry and agriculture have long been unable to manage without them. We are living in the plastic age! And, perhaps most importantly: As a producer of plastics, the chemical industry has absolutely no interest in curbing consumption. After all, plastics are basically just a waste product of oil processing that can be used to make a lot of extra money.

BIOPLASTICS ARE NOT ALWAYS ORGANIC

Let's move on to self-deception, another all too human reaction to the misery. When the realization dawns that we and plastic can't go on like this, we like to look for quick and easy solutions. For example: bioplastics. Sounds good too. Unfortunately, the reality is much more complex. The exact meaning of terms such as compostable plastic or bio-based plastic is not regulated by law. As a customer, I have to trust the information provided by the manufacturer. One example: the bin liners made from biodegradable plastics that many people use to collect and dispose of organic kitchen waste. In principle, the statement that the mostly green (!) films actually decompose into water, CO2 and biomass is correct - but only under certain conditions. And these conditions do not necessarily prevail in the composting plant of the local waste disposal company. The organic waste usually does not remain in the plant long enough for the plastic to decompose completely. Many sorting plants are also unable to distinguish organic plastic from "normal" plastic and sort the bags out straight away. And even if composting works: Biodegradable plastics can contain harmful substances. This applies not only to bin liners, but also to disposable tableware and packaging. Unfortunately, it borders on self-deception to simply replace one plastic with another, supposedly greener one. So far, there are no convincing non-toxic and easily degradable plastic-based alternatives. Consumers who want to make reasonably sensible purchasing decisions must therefore inform themselves very carefully. But who can always do this in everyday life?

Everyday reality in the supermarket: products elaborately packaged in plastic

Bakelite is heat-resistant and non-conductive. Perfectly suitable for electrical appliances

Granules of polypropylene. Encountered and used in everyday life as film or packaging

A third common reaction to our toxic relationship with plastic: condemnation. As if plastics were fundamentally evil, they are shunned, even downright demonized. Of course, it is good and always justified to question our own plastic consumption and rethink old habits. The "zero waste" movement, for example, has developed many creative tricks and tips on how to avoid plastic in everyday life. But there are also plenty of useful plastic products that cannot simply be replaced. In the medical sector, for example, as the pandemic has shown quite emphatically. Disposable protective masks made of artificial fibers cause enormous mountains of waste worldwide, but have also saved countless lives and saved many people from serious illness - in case you needed any more proof of how complicated the human-plastic relationship is. Hoping that microorganisms will simply eat our plastic waste at some point is not a solution either, given the urgency of the situation. Although there are initial promising research results, for example with bacteria that can digest polystyrene, this has so far only been successful in the laboratory.

precious plastics

So how do we get out of this toxic relationship? By trying to adopt a new perspective on plastics and seeing them as a valuable resource. After all, the core of the plastic problem lies in the fact that most plastics are so cheap to produce. Our treatment of them is correspondingly careless. But if they were precious, our behavior would change and we would be much more aware of how we use them. In view of the lobbying power of the oil-processing industry and the power of the plastic habit today, this is unfortunately just a mind experiment, but a productive one for understanding how we can use plastics more sensibly. Everyday disposable products such as packaging would then be far too expensive. Manufacturers and retailers would have to look for alternatives, set up reusable systems - and we would have to get rid of one or two conveniences. We would also no longer be able to afford to simply throw away and incinerate plastics.

If newly produced plastic were a valuable resource, then reusing and recycling it would also be worthwhile. All kinds of products would be collected, sorted and fed back into the material cycles as a matter of course. Accordingly, many objects would be designed in such a way that they could be easily broken down into their individual components. And last but not least, we would use plastics primarily where they are used for a long time and where the financial outlay is worthwhile. Price would no longer be the decisive factor, but rather the special properties of individual plastics that make them superior to other materials in certain situations. With this change of perspective, many conflicts in this complicated relationship will resolve themselves. At the moment, as I said, it's just an almost seductive mind game. But also as a very pragmatic testing tool for our daily consumer decisions, always based on the question: do we really want to afford this plastic product? Not always, but much more often than today, the answer would then be: No.

Pictures: Oleksabdr, Adobe Stock; Dario Sabljak; saravut, Adobe Stock; Peter Stackpole/ The LIFE Picture Collection/ Shuttershock; Xavi Cabrera, Unsplash

NOT ALL PLASTICS ARE THE SAME

PET, PP or PVC? Who knows for sure which plastic is behind which abbreviation and what it is suitable for? Find out more about seven products from the MAGAZIN range and the plastics they are made of in the glossary.

TAKE THAT BACK

A new product that was designed back in 2010? That's the REX chair by Ineke Hans. The Dutch designer had already developed Rex a few years ago, as a plastic chair made of parts that are easy to separate. The Circuform brand then brought it back onto the market, made from recycled polycaprolactam (PA6) - and with a return promise! Anyone who buys REX can be sure that the manufacturer will take the chair back one day - and refund the chair's current material value. The idea behind this: Plastic can only be recycled efficiently if you know the exact composition of the material. Ideally, a plastic product should be returned to its origin at the end of its life cycle. Experts have been calling for corresponding take-back systems for the furniture industry for some time - with REX, Ineke Hans and Circuform are now squaring the circle for the first time with a reality check.

Ineke Hans

The designer is Professor of Product Design at the Berlin University of the Arts, has studios in Arnhem and Berlin and designs products, furniture and exhibitions. During her time in London, she initiated "Salon", a series of discussions on the future of furniture design. Ineke Hans has worked for numerous well-known companies in the design industry and helped to launch the German Design Graduates platform for young talent. Picture: Jorit Aust

ABS / bicycle helmet CHAPTER

The outer shell of the CHAPTER bicycle helmet is made of acrylonitrile butadiene styrene, ABS for short. ABS is a thermoplastic that can be heated and shaped several times. It is also unbreakable, dimensionally stable and relatively light. Most people know it from their childhood days: LEGO® bricks are also made of ABS.

PP / Atlas drawer

Polypropylene (PP) is also a thermoplastic, free from plasticizers and easy to recycle. For example, we have the drawer for our ATLAS container made from PP.

EVA / Mesh bag case

The MESH BAGs are made entirely without plasticizers or PVC - the films are made from ethylene vinyl acetate, or EVA for short. A lightweight and elastic plastic that can be recycled. Good to know: EVA is also non-toxic and food-safe, in case the MESH BAGs are spontaneously converted into a snack bag.

Silicone / Soap dish Float

Silicone is the ideal material for the FLOAT soap dish. It is waterproof and easy to clean, making it easy to remove soap residue. At the same time, it protects the surface thanks to its softness. Because silicone can withstand temperatures of 200 to 250 °C, depending on its composition, it is often used for kitchen products.

rPET / Mat Liv

Polyethylene terephthalate is one of the most common plastics - everyone knows the PET bottle. The LIV mat is made from just such bottles, collected in India - the country with the highest proportion of recycled material in the world - and processed into rPET yarn. LIV dries quickly and is easy to wash, making it ideal for balconies and patios.

Plastic is a matter of habit. Let's be aware of where plastic can be found. A few examples:

Composite cartons Beverage cartons, milk cartons, juice boxes, even wine are available in square packaging. Everything that is liquid is filled in composite cartons. But if you dispose of them in the paper waste, you're looking at the wrong garbage can. This is because the boxes are only made of cardboard on the outside and are lined with aluminum and polyethylene on the inside. Good for tightness, bad for recycling.

Powder coating How does the color get onto the metal? By powder coating. This is much more durable and therefore longer-lasting than conventional paintwork. But the paint particles are made of petroleum plastics, and epoxy and polyester resins are often used in powder coating.

Cold foam mattress Their ergonomic qualities are impressive - their ecological footprint not so much. Cold foam mattresses consist of foamed polyurethane, usually petroleum-based, sometimes replaced by natural oils. At the end of their life, the mattresses are usually simply incinerated. However, a new chemical recycling process is about to be launched. Important for recycling: the separability of the individual components of a mattress.

Sneakers Everyone loves sneakers - and hardly anyone thinks about the environment. Most sneakers are a firmly glued, almost inseparable conglomerate of various petroleum-based plastics such as polyurethane, EVA, polyester, polyamide and synthetic rubber. End of the line: waste incineration.

More on the subject of plastic

Everyone should be aware by now of how destructive the unbridled production and use of petroleum-based plastic can be. That is why alternatives have long been researched. In their studio in a former paint factory near Amsterdam, the duo Klarenbeek & Dros are working with algae and fungi on the plastic of the future. Not only should it be compostable and protect the environment, its production should also bind CO2 - and even promote biodiversity.

Mattresses crumble, computer cases turn yellow, coatings become sticky: plastics may be considered durable, but they age just like any other material. Tim Bechthold, restorer at Munich's Die Neue Sammlung design museum, explains how plastics degrade and which piece of furniture is his biggest problem child.