Only with us!

With passion, wit and a sense of quality: MAGAZIN has been developing furniture under the name MAGAZIN for around twenty years and has it manufactured in Germany and Europe. Text: Jasmin Jouhar

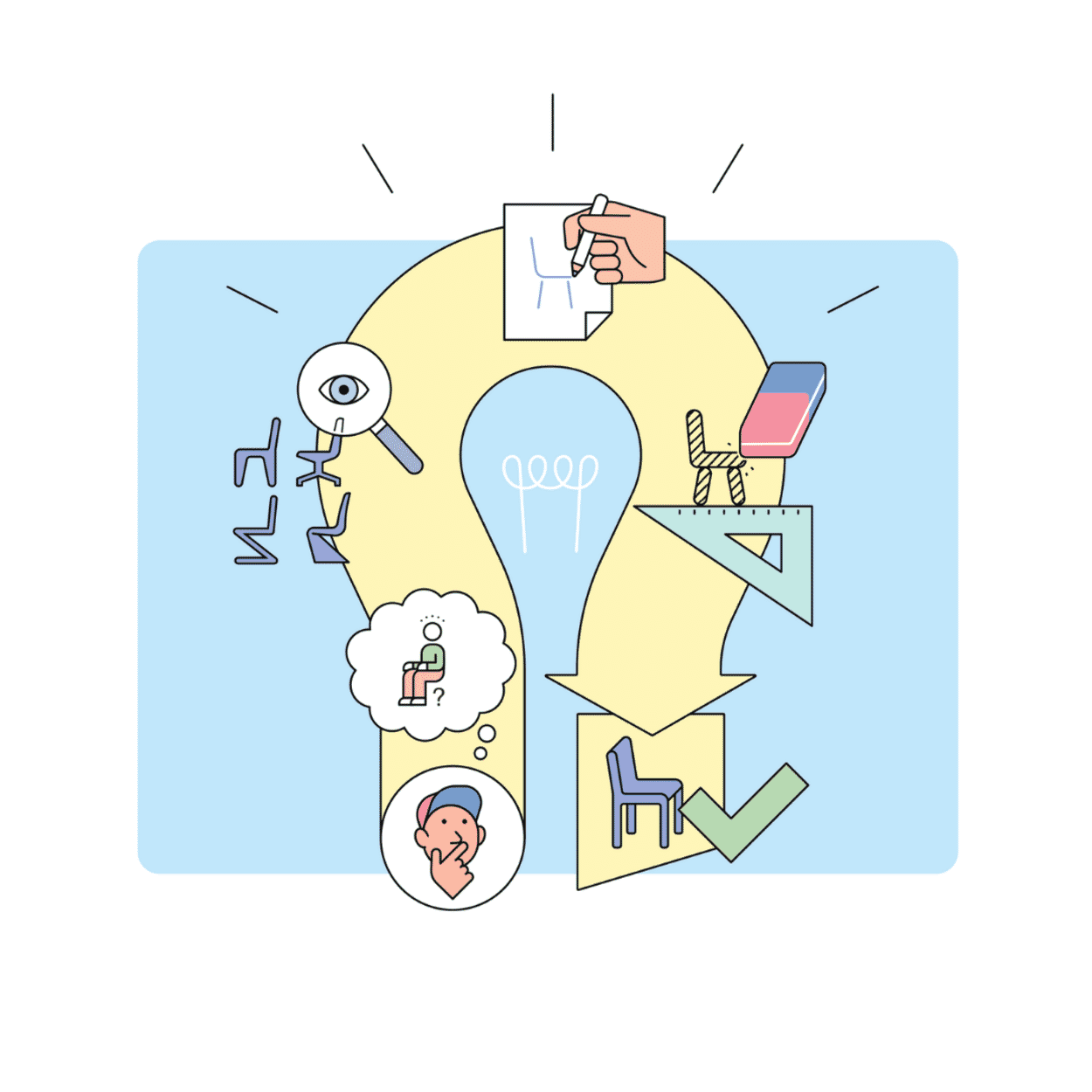

So why did MAGAZIN take the plunge around twenty years ago and add self-developed furniture to its range as a retailer? Because there were always gaps in the range that the product scouts at MAGAZIN were unable to close with what was available on the market. The gaps are made visible, for example, by a suggestion from the customer or by an existing but not quite as convincing solution for the requirement. "We can do better than that," summarizes former MAGAZIN Managing Director Stephan Dornhofer, who initiated the collection of MAGAZIN products at the time. A suggestion from a designer, an idea from the MAGAZIN team itself or collaboration with universities also provide impetus for a new product. And, last but not least, it is the joy of playing with materials and ideas. Today, the range developed in-house includes a variety of products and product families. They are sold under the brand MAGAZIN-Produkt and are available in the online store at MAGAZIN and in the three MAGAZIN stores in Stuttgart, Bonn and Munich. The latest additions include the P100 cabinet, ZEHDENICKER table and EINSER chair designed by the MAGAZIN team. The storage unit CONTAINER DS by Basel designer Kuno Nüssli is already a classic. Inspired by the typical overseas container, CONTAINER DS is a perfect example of what makes a MAGAZIN product. "It should speak to you, tell a story," says Stephan Dornhofer. At the same time, it should address a specific living theme and offer users a solution - in the case of the CONTAINER, of course, the tiresome topic of storage space. The design language of the MAGAZIN products is functional, concise and independent: The functionality of a piece should always be readable, for example, and processing details are part of the design. "We don't hide any fittings, show screw heads or tolerate plastic caps on pipe ends," says Dornhofer. And a wink makes some products even more accessible.

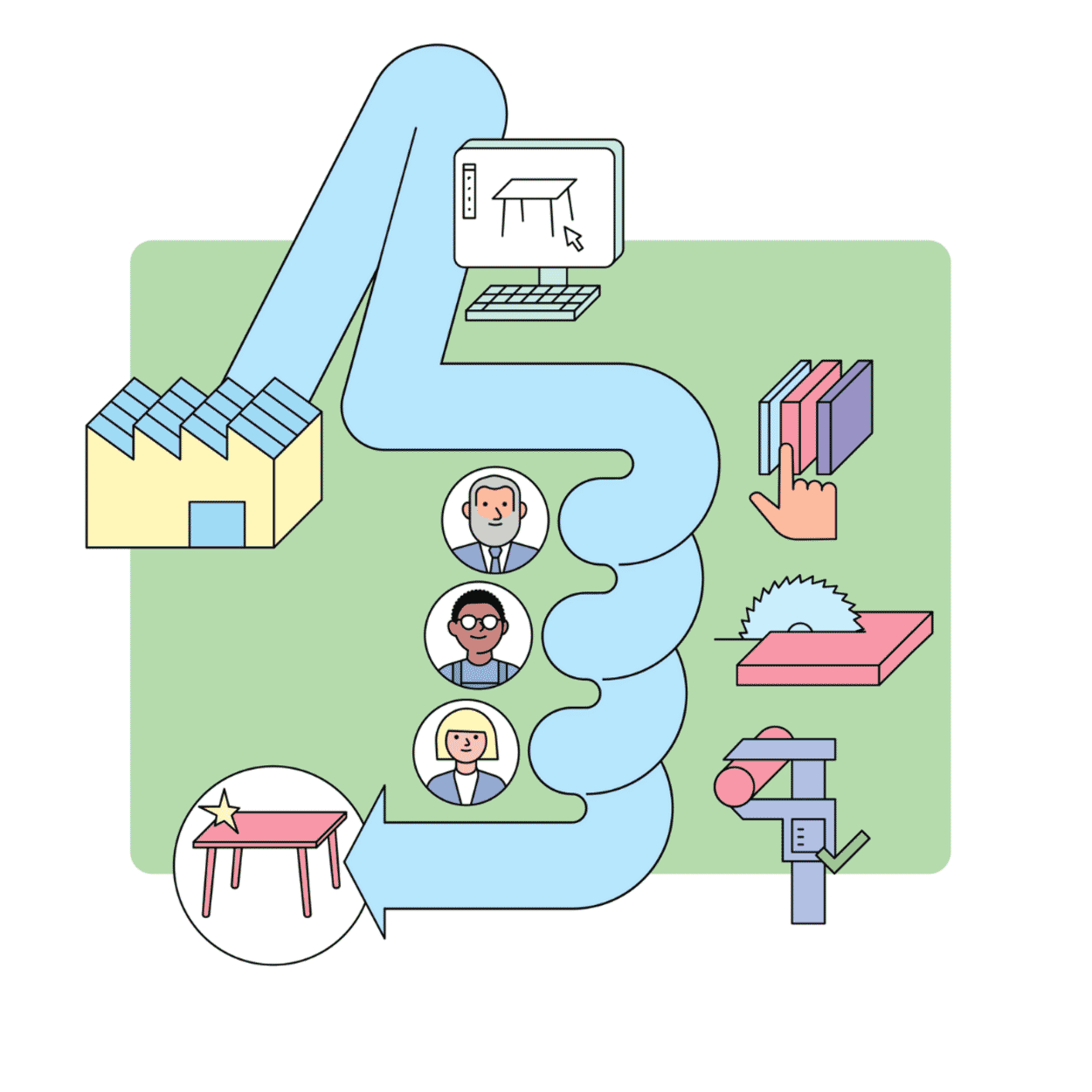

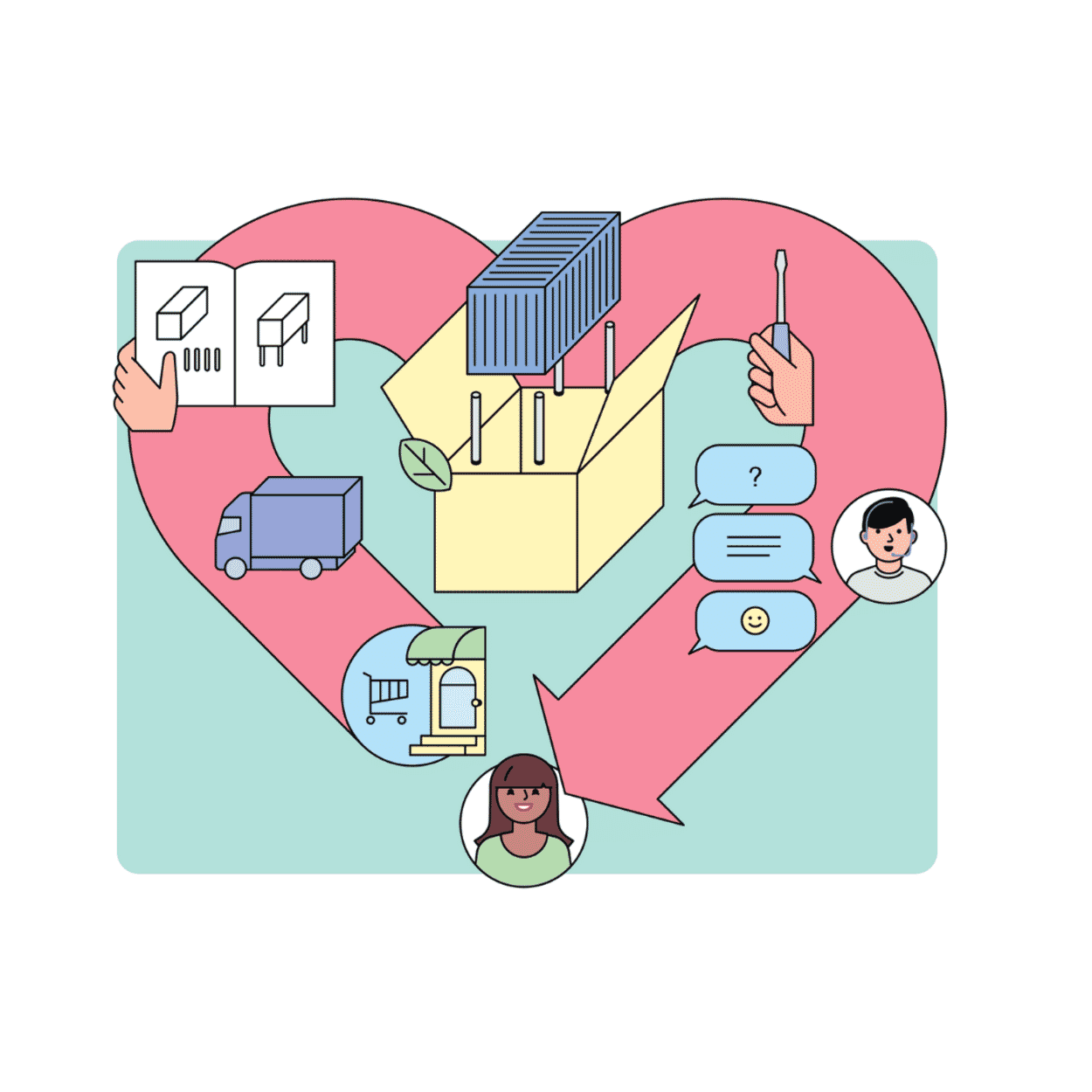

It is part of MAGAZIN's philosophy to produce in Germany and neighboring countries wherever possible - and has been since the very first MAGAZIN product, the shelving system 1HOCH3 from 2004. CONTAINER DS, for example, which is now represented in museums and collections, is manufactured by Oskar Zieta in Poland. The designer and entrepreneur from Zielona Gora was instrumental in getting Kuno Nüssli's design ready for series production. According to Dornhofer, the number of CONTAINERs produced each year could now fill a large Rhine freighter. The close, continuous collaboration between the in-house product development team in Berlin, led by Daniel Kern, and carpenters, metalworkers and textile companies has generally proven its worth. This allows MAGAZIN to ensure that the quality of the furniture is right and that environmental and social standards are adhered to. In addition, the work on a product is not finished when it is launched on the market. The range needs to be maintained, for example with new variants and custom-made products, materials need to be replaced or packaging improved. Stephan Dornhofer calls this "aftercare" - an effort that should not be underestimated.

Producing its own products has also sharpened MAGAZIN 's focus on what other manufacturers offer. With the experience and knowledge gained from almost twenty years of MAGAZIN products, the company now selects its range more carefully, particularly in terms of sustainability and durability. This all goes to show: Producing your own range as a retailer is not a hobby. It is a logical consequence of the passion for a well-designed product. The economic balance sheet is also positive: The MAGAZIN products have developed into a solid mainstay for the company. They shape the identity of MAGAZIN and are a unique selling point. Because: CONTAINER DS, GURTBETT, SCHLUND and all the others are only available here. pictures: Dirk Rittberger 1: A brilliant idea also consists of needs analysis, market research and prototype production 2: The best quality has many parents, e.g. 3D models, material testing and optimized series production 3: From the heart: Presentation, smooth delivery and customer service are crucial when it comes to customer contact