IS THAT FINISHED?

Raw, unadorned, radical - galvanized surfaces have a special aesthetic and often develop a fascinating beauty in combination with the material, shape and surroundings. At MAGAZIN, we value the material and use it in various products. And we are not alone in our appreciation. Examples can also be found in art and architecture.

Text: Thomas Edelmann

ART, GALVANIZED

Art as an object of utility that not only enables change, but actually provokes it: That was the idea of Charlotte Posenenske (1930-1985). In 1967, she created her "Series D", square tubes made of galvanized sheet steel, similar to functional ventilation components. Her manageable artistic oeuvre, which was received worldwide, was created between 1956 and 1968. She wanted to undermine and override the mechanisms of the art market. As her companion, the gallery owner Paul Maenz, recalled, she therefore sold her works "unlimited, unsigned and at cost price". The student of Willi Baumeister had designed stage sets before turning to art. "The things I make," she wrote in her 1968 manifesto, are "changeable, as simple as possible, reproducible." They are "like building elements, they can be changed into ever new combinations or positions, thereby changing the space." Her works have been presented in galleries, in the hangar at Frankfurt Airport and in public spaces. "The objects," wrote Posenenske, should have the "objective character of industrial products. They should not represent anything other than what they are." When her manifesto appeared, she had already stopped making art. Studying sociology, focusing on work processes, seemed more appropriate "for solving urgent social problems."

Picture: Reproducible and movable: "Series D" made of galvanized sheet steel (1967) by Charlotte Posenenske.

ARCHITECTURE, GALVANIZED

The former working-class district of Le Plateau in Montreal is now a sought-after residential area. An old shed, typically only 120 square meters in size, was converted and extended by a family from the architecture firm TBA. Flat galvanized panels characterize the minimal intervention. The main task was to extract "as much living space as possible" from the existing building. The small side courtyard was to be retained at all costs. The solution was an extension that bridges the courtyard on the upper floor and docks onto the neighboring house. The addition - only 28 square meters in size - forms a strong contrast to the existing building. The panels reflect the light, giving the extension a feeling of lightness. The surroundings of Casa 905 in the small town of Igualada, near Barcelona, are heterogeneous. Traditionally a garden city, next door are banal buildings and residential towers from the sixties. The couple with two children who live here have a soft spot for contemporary Japanese residential buildings. The Harquitectes office created a compact house for them with a functional outer skin made of galvanized corrugated sheet metal, which provides passive ventilation in summer. The windows are fixed, while the panels on the first floor are movable. They provide privacy as well as views of the garden. Charles Moore's Orinda House (1962) and Lina Bo Bardi's Santa Maria dos Anjos Chapel (1977) served as inspiration.

Picture: Increased living space with a shiny outer skin: The addition to a gutted carriage house in Montreal.

WHAT DOES GALVANIZED ACTUALLY MEAN?

Galvanized surfaces are particularly hard-wearing, abrasion-resistant and protected from the weather. And - galvanized materials are easy to reuse and recycle. But what exactly is galvanizing? We introduce you to the two processes.

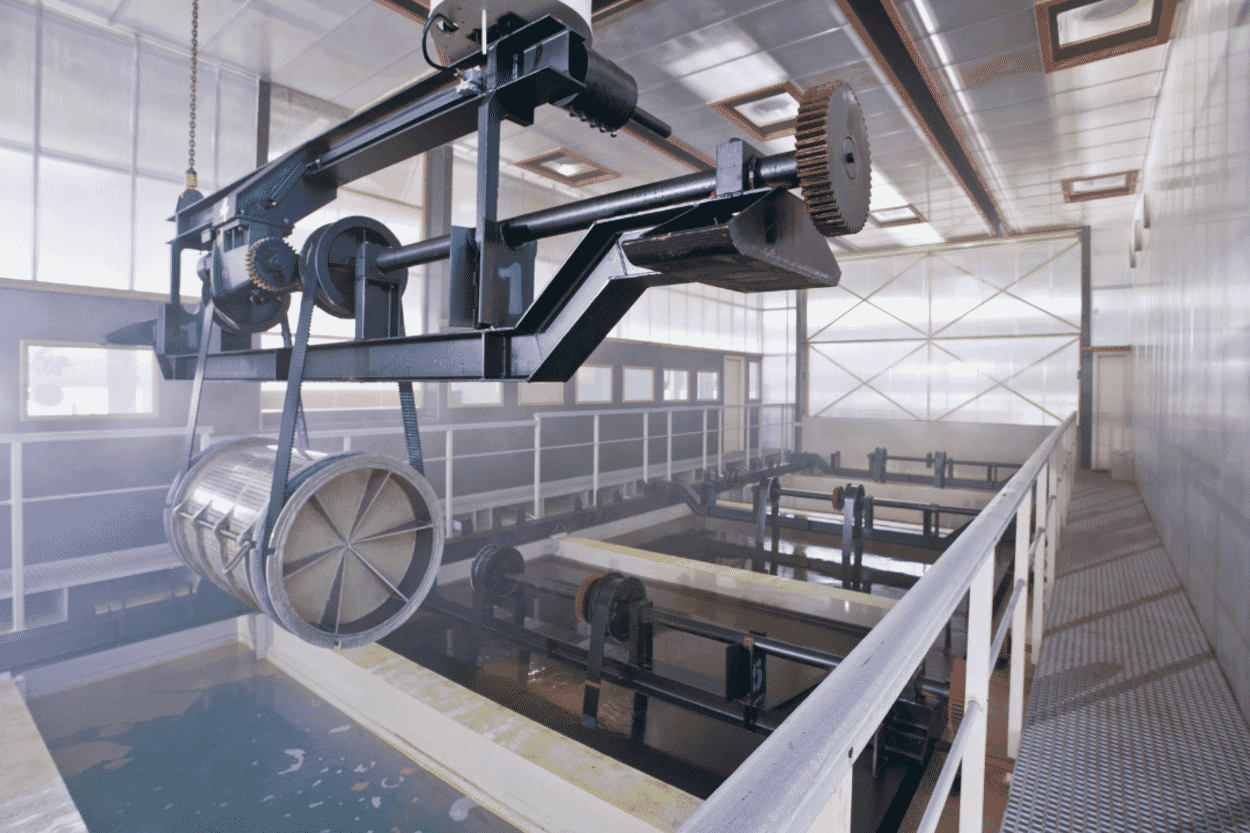

HOT DIP ZINCING

No, nothing burns during hot-dip galvanizing and an open flame is not needed either. However, it does get fiery hot, because the steel is bathed in zinc at around 450 °C. Depending on the process, either individual workpieces such as steel grids or beams, but also finished products such as garden furniture, are immersed in the molten zinc. Or steel strips are drawn through the molten zinc. This creates an even coating. Hot-dip galvanizing is frequently used, especially for industrial and architectural applications. However, due to the high heat, it is only suitable for components that are not sensitive to warping. The surface of the zinc coating is matt silvery, sometimes uneven, and the often somewhat coarser character gives it a special industrial aesthetic. So when the going gets rough and the weather is tough all year round, products need to be hot-dip galvanized.

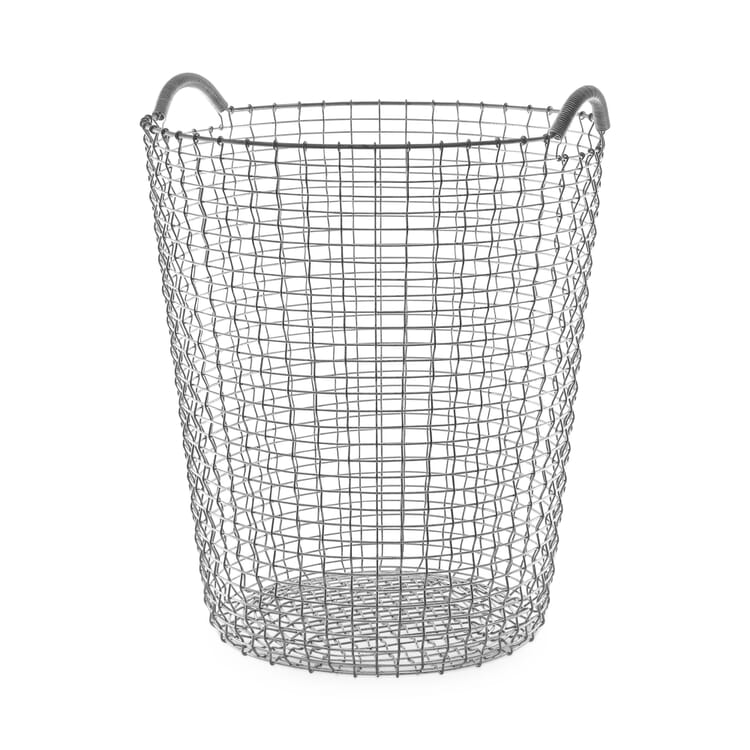

ELECTROGALVANIZING

In galvanizing, the steel is galvanized by electrolysis. Anyone who remembers their chemistry lessons will know that this has something to do with electricity. In this process, pure zinc and the workpieces to be galvanized are placed together in an electrolyte bath. When direct current is applied, particles of the less noble zinc are released and deposited on the more noble steel. Although the coating is thinner than with hot-dip galvanizing, the surface is particularly even - and also protected from the weather. Thanks to the wafer-thin material application, the surfaces are suitable for further processing, such as painting or powder coating. Due to the comparatively thin zinc coating, the process is also recommended for smaller components such as screws and other fittings. Electrogalvanized surfaces often have a slightly iridescent sheen.

Pictures: Adrià Goula; Patxi Bergé; Adrien Williams; bogdanvija, Adobe Stock; Josef, Adobe Stock

INDUSTRIAL TOUCH: MAGAZIN-PRODUCTS MADE OF ZINC

What does that actually mean...?

Corrosion protection usually means applying an additional coating. With aluminum, however, a little oxygen is enough. In the electrolysis process, the metal forms a hard and durable surface of aluminum oxide on its own. And it can even be colored

Durable, versatile, low-emission, efficient. Powder coating may not sound so glamorous, but if you want a colorful finish, there is hardly a better process for surface protection. Thanks to electrostatic effects, perfect surfaces can be produced. And when the going gets tough, they show character.