The House of Europe

Why regional production is coming back

For a long time, it was considered a foregone conclusion: cheap products come from abroad. Often enough, this was also the reason for opening up international supply chains. The war in Ukraine and the coronavirus crisis have shown how vulnerable our economy is. Can we free ourselves from these supply chains? What about Europe as a location for innovation? What are the advantages of producing locally? And how does all this influence our purchasing decisions? A stocktaking.

Text: Jochen Overbeck

Embracing traditions

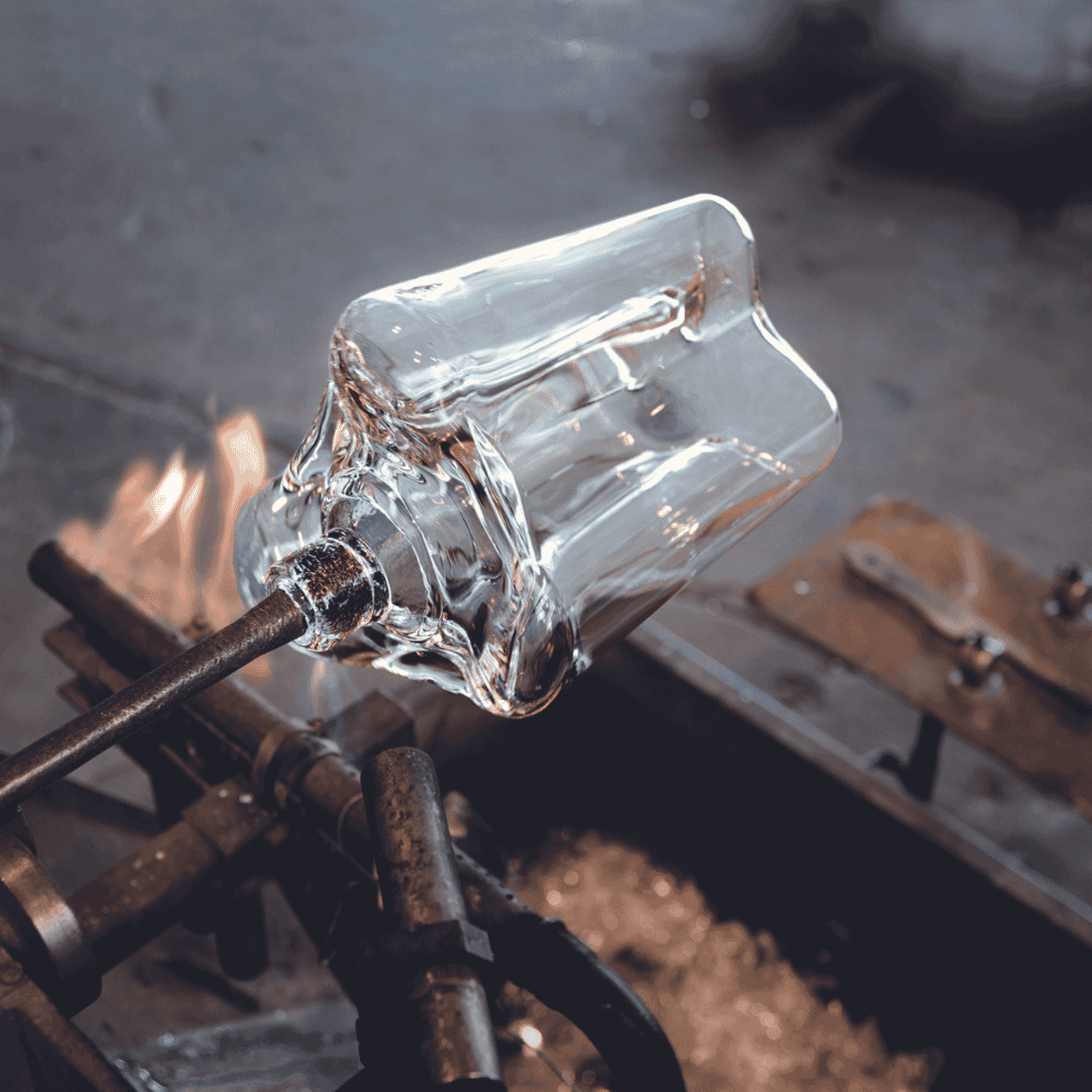

The first has a lot to do with identification. We have an image in mind when we think of European products. An Italian hat factory. A glass-blowing factory in Finland. A car manufacturer in Germany: we know about the history and tradition of these companies. The hat from the Marche still resembles the one worn by workers in the fields 100 years ago. The glass from Finland is a design that was already a success at the Milan Triennale in the 1950s. At the same time, European companies are continuing to develop: 50 years ago, the car manufacturer from Germany stood for cars that ran, ran and ran. And today? It is regarded as a globally respected driver of innovation. All these examples show how tradition and progress are often intertwined in Europe and help to define our identity. Sometimes, however, we also fall prey to our Eurocentrism. Despite the cheap goods that jump out at us every day from ads on Facebook, Instagram and the like, it is by no means the case that a product made in Asia is automatically worse than a European one.

Standard and sustainability

But we rightly trust what we think we know. Manufacturing in Europe follows a common set of values that has manifested itself in certain standards. These concern products - such as their energy efficiency or materiality - but also the circumstances of their manufacture. For example, there is a statutory minimum wage in 21 out of 27 EU countries, and the EU Supply Chain Act applies throughout the EU. It is intended to ensure that human rights and environmental protection regulations are observed. All of this provides us citizens with security and reliability when making purchasing decisions. The third reason is related to the first two: In most cases, a locally manufactured product is more sustainable. Shorter transportation routes reduce delivery times and lower a product's carbon footprint. Communication and quality assurance are simpler, which leads to a longer service life. None of these are new ideas. But for a long time, they were only relevant for a small number of German companies, as it was often said from the 1990s at the latest: good is what saves costs. And you save costs if you buy or produce where it is cheap. Stinginess is cool, many will remember.

Traditional European craftsmanship: glassblowing

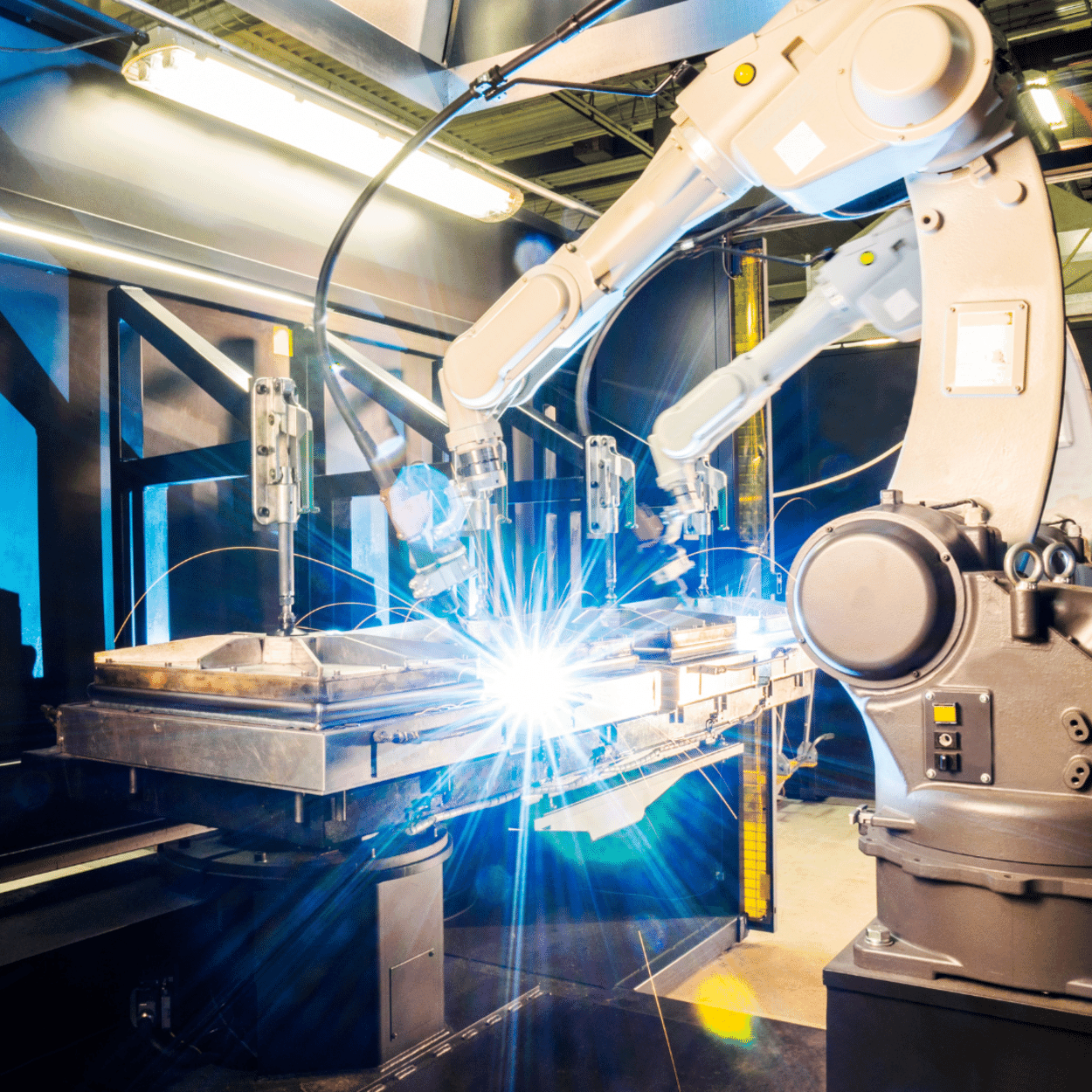

Automated production can also work in Europe

Unfamiliar experience: empty supermarket shelves

The fragile present

The crises of the past three years show just how fragile this model is: even those who are not aware of the large flows of goods will have read the small messages. In November 2022, for example, Apple was forced to post a notice on its website: Due to Covid-19 restrictions in Zhengzhou, China, shipments of the iPhone14 were lower than forecast.The Russian war against Ukraine also had an impact on trade: Many trade routes passed through Russia, Belarus and Ukraine. Products arrived too late or not at all. The consequences are more immediate when it comes to goods from the countries involved: Germany's winegrowers, for example, were confronted with rising glass prices after the start of the war: The glass often came from Ukraine. In turn, glass produced in other European countries became even more expensive than before due to the rise in energy prices. The prices of paper, wood and industrial metals also came under pressure. In the face of this cost explosion, large retail chains questioned practices that had previously been considered irrevocable - such as the millions of printed weekly advertising brochures. Another disaster also underlined the extent to which we are dependent on the international commodity economy: In March 2021, the container freighter "Ever Given" ran aground in the Suez Canal. The canal proved to be a - now blocked - bottleneck. 422 ships were stuck in traffic jams around this most important passage for international shipping. The delay in unloading the goods continued to have an impact for months and presented ports and the shipping industry with immense logistical challenges.

Back to start

One of the strongest images of the accident showed an excavator that looked like an orange children's toy next to the large freighter. The construction equipment and the giant pot quickly became a meme: If one cog gets stuck, the entire machinery of the global economy grinds to a halt. The bad news is that this situation is unlikely to change much in the next few years. Or is that actually good news? "Companies need to rethink", wrote Handelsblatt back in 2021, and continued: "Global trade has become fragile - the illusion that every product is available at every location to the minute is shattering." New opportunities are indeed emerging from this crisis. One term that has recently become increasingly common is "reshoring". This is the term used to describe the relocation of production facilities back to Europe. The fact that reshoring has become an issue is not only due to the aforementioned uncertainties, but also to increased transportation costs. These quickly outweigh the financial benefits in other areas, such as wages.

A shared doorbell sign

In the meantime, the EU is working flat out on a "Made in Europe" program. It is primarily a response to the US "US Inflation Reduction Act (IRA)", which is intended to promote green technologies within the USA. The EU is more concerned with protecting its own exports than with strengthening the domestic market. Incidentally, the "Made in EU" label has existed since 2003, but it is not used. In 2021, another initiative set out to install a corresponding seal of quality. The response from industry was hesitant. Perhaps many countries prefer to trust the appeal of their own brand. Doesn't a unilateral "Made in Germany" sound much snappier? Anyone who thinks so should take a look at the history books: This designation of origin was originally introduced in Great Britain at the end of the 19th century to identify Germany's inferior goods at the time. Their quality improved in the years that followed, but the national industries' fear of separation is still surprising, at least if we return to the image of the European house mentioned at the beginning.

Pictures: Michael Hausmann, iStock; Timo Juntilla; Fertning, iStock; SolStock, iStock

HOMEMADE - THIS IS HOW IT WORKS

A few figures: 70 percent of European active pharmaceutical ingredients come from China. So do 80 percent of our laptops and 70 percent of our cell phones. Our exports to China are manufactured in Germany by one million workers. So the dependencies are enormous and there are no simple solutions. It's time for us to focus on our own skills! Six examples of regionally manufactured products and the story behind them.

CONTAINER DS

Container DS, with lock, RAL 1016 Sulfur yellow

Idea and design from Switzerland, steel from Sweden, engineering spirit from Poland. CONTAINER DS is manufactured in the production facility of architect, inventor and entrepreneur Oskar Zieta in Zielona Góra, 200 kilometers from Berlin. Smart production, local suppliers and dedicated entrepreneurship result in innovative cabinet furniture.

REX CHAIR SERIES

Rex armchair, Gray / Black / Black

Made from recycled polycaprolactam (PA6) and recyclable! These are the striking features of the REX chair by Ineke Hans. The chairs produced from a recycled material can be returned directly to the Dutch manufacturer CIRCUFORM at the end of their life cycle. With this closed cycle, the manufacturer is setting a new standard for the use of plastic.

Sofa bed Nova

Sofa bed Nova

The NOVA sofa bed comes from SOFTLINE, based on the Danish island of Funen. SOFTLINE is one of the market leaders in the processing of high-quality upholstery foams. All upholstery work is carried out at the main factory in Maribo, where innovative materials are experimented with and sustainable solutions are researched. For example, water-soluble and solvent-free adhesives have been used for some time now. The wooden frames in the extensive range come from sustainable forestry in Sweden. Cooperation with suppliers from Poland, Italy and the Czech Republic makes SOFTLINE a truly European manufacturer.

Icaro7 cutting machine

Cutting machine Icaro7

Kitchen and household appliances often find their way to us from Asian manufacturers. This is not the case with appliances from RITTERWERKE, founded in 1905 in Gröbenzell, Bavaria. Here, the company does not limit itself to the design and final assembly of components manufactured in Asia - the entire vertical range of manufacture is produced in the German province. Made in Germany" is firmly anchored in the company philosophy and secures and creates jobs, guarantees high quality standards, repairability, functional use of materials and a clear design language.

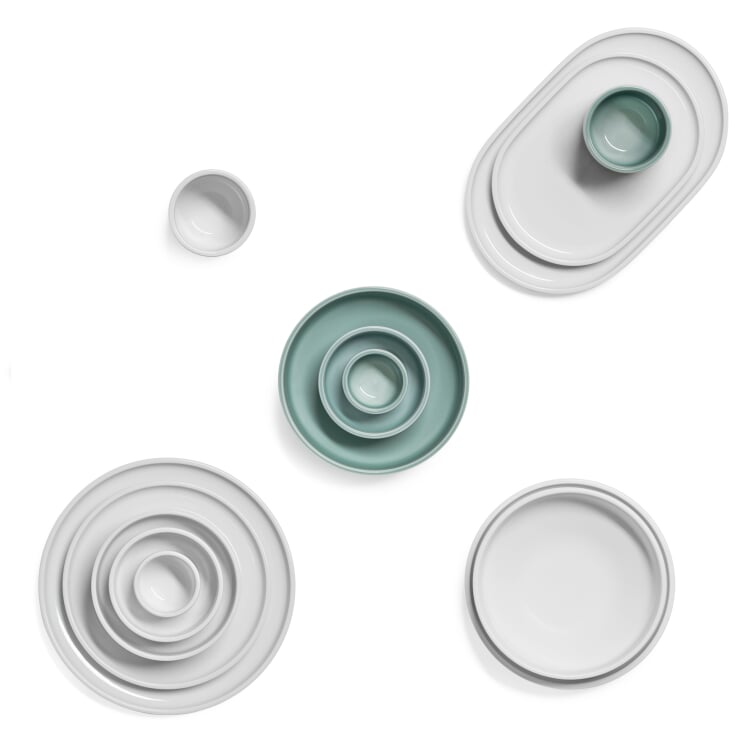

Tableware series Shiro

Tableware series Shiro, Dessert plate

The history of porcelain production in Germany is multifaceted, characterized by a long tradition in both the manufacturing and industrial sectors. However, in times of changing consumer behavior, porcelain companies have already experienced deep crises. SCHÖNWALD is the name of the brand that has been producing hard porcelain at its site in Upper Franconia for around 150 years, primarily for use in hotels and restaurants. The SHIRO tableware series breaks with the conventions of classic porcelain thanks to a variety of new shapes and applications. An innovative product that is manufactured at SCHÖNWALD in a modern production facility.

More on the topic of globalization

Globalization, says Stefan Diez, is not a bad thing per se. But if it only leads to cheap production, it prevents innovation and destroys the know-how of local companies.